From project to partnership – LMT expands and optimizes NC programming with ScaleNC

Summary

Efficiency, reliability and production quality have always been top priorities for LMT Leuchten + Metall Technik GmbH from Hilpoltstein, Germany. In order to continue to provide its customers with the best results during a transitional phase as part of its digitization strategy, the Middle Franconian company decided to rely on ScaleNC's expertise until its own resources were available for the deployment of new software solutions. This initial project has since grown into a lasting partnership in machine programming. ScaleNC's professional CAD/CAM services and cloud-based platform have become an integral part of LMT's work preparation processes. The company can now focus even better on its core competencies and significantly reduce the workload of its own employees, especially during peak demand periods.

About the customer

LMT GmbH has been a specialist for customized object lighting and sophisticated metal constructions, especially in medical technology, for more than 30 years. Together with renowned clients, lighting designers, architects and building contractors, the owner-managed family business with 50 employees develops and implements complex lighting and metal construction solutions for architectural and infrastructure projects, such as airports, cultural and monumental buildings, as well as complete systems for train stations and subway stations.

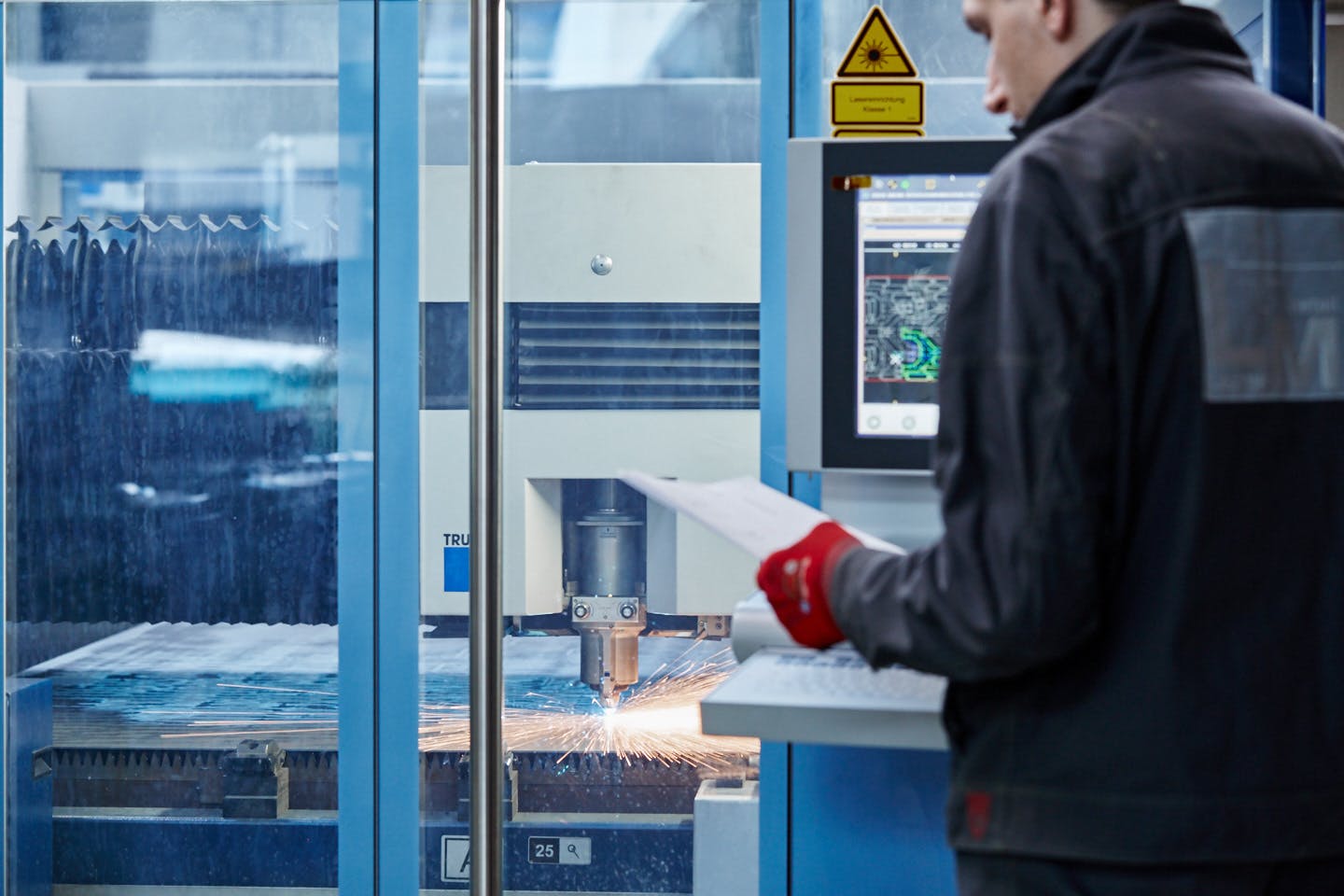

The modern machine park with TRUMPF machines for laser cutting, die bending and panel bending (TruBend Center) reflects LMT's high demands on the quality of its own products.

Fast and flexible – but also challenging when it comes to NC programming: TRUMPF TruBend Center 5030 panel bending machine at LMT

The challenge

The continuous optimization of its manufacturing processes plays a central role for LMT as a manufacturer of project-related and complex lighting and metal construction solutions. Quality and efficiency are regularly evaluated in order to meet the company's own requirements as well as the expectations of its customers. An essential component in this regard is the use of state-of-the-art technical solutions in the field of NC programming.

LMT had previously programmed its own sheet metal fabrication machines in-house using the standard TruTops product from TRUMPF. However, especially at peak times and during vacation or sick leave, this meant that planning and production processes could not be carried out with the desired efficiency and delivery dates were put at risk. The company was therefore looking for a solution that would reduce the workload of its employees while at the same time meeting its high manufacturing standards.

In addition, as part of its own digitization strategy, LMT planned to switch to TRUMPF's TruTops Boost software for NC programming, but did not have the necessary personnel resources for the parallel operation and seamless transition required during the initial phase.

Why ScaleNC?

Since the professionals at ScaleNC have been programming TRUMPF machines with TruTops Boost for many years, the team from Stuttgart was LMT's first choice.

The plan was clear: For the transition period until the new TruTops Boost system was in place, ScaleNC would do the programming for LMT. At the same time, the programming process should also be adapted with TruTops Boost: In CAD design, the manual creation of unfoldings and the creation of bending drawings were to be eliminated in the future so that the saved time could be used for other tasks. In addition, Model-Based-Definition was to be introduced for sheet metal parts and for assembly components. LMT wanted to test these approaches extensively using NC programming with ScaleNC before introducing them.

The solution

In April 2021, the decision was made to go the way together with ScaleNC. The start of the collaboration was straightforward. After a brief introduction to ScaleNC's online platform, LMT's designers and programmers were able to start working directly, hand over CAD data and, after processing by ScaleNC, download the finished NC programs in less than 24 hours in most cases. On a monthly basis, ScaleNC was able to provide cutting and bending programs for a three-digit number of sheet metal components for LMT. The NC programs were then transferred directly to production. Thanks to the intuitive online platform, ScaleNC was used very quickly and frequently by LMT's employees. Billing was done via a monthly flat rate, which made working with ScaleNC predictable and calculable for LMT.

«A hybrid model, where we can leverage our internal resources while at the same time drawing on ScaleNC's expertise and performance, gives us the best of both worlds.»

Mike Otterpohl, CEO & Managing Partner, LMT GmbH

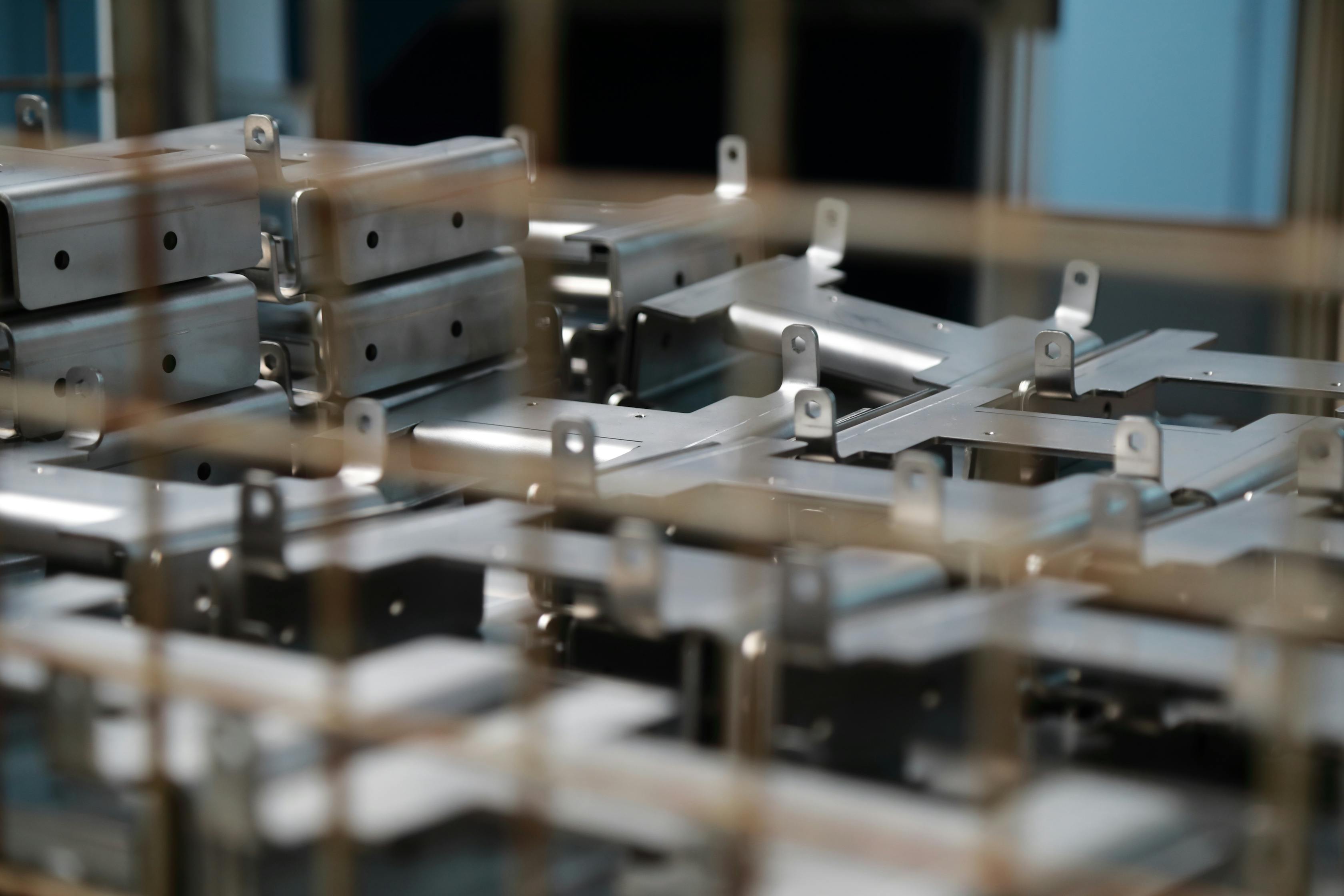

Perfectly cut and bent – precise sheet metal parts with NC programs from ScaleNC

The result

ScaleNC was able to support LMT efficiently and focused during the transition phase to TruTops Boost. Both the ScaleNC platform and the flexibility of the young team from Stuttgart were convincing.

Since then, LMT has continued to make regular use of ScaleNC's services, for example for demanding components or high workloads. The initial cooperation has become a long-term collaboration. LMT particularly appreciates the flexibility: the services used can be adjusted as needed, while the costs always remain calculable and comprehensible.

In the future, LMT plans to continue working with ScaleNC. Especially during peak periods with high workloads, it is essential for LMT to make optimal use of the existing potential of its modern equipment. ScaleNC supports the company with its experts, who also assist their customers with new ideas or alternative solutions for more efficient programming, if required. The goal is always to obtain the best possible result in the manufacturing process. “A hybrid model, where we can leverage our internal resources while at the same time drawing on ScaleNC's expertise and performance, gives us the best of both worlds,” explains Mike Otterpohl, LMT's CEO and managing partner. “On the one hand, we don't give up our own expertise, and at the same time we can ensure that ScaleNC will always help us produce quickly and with high quality, even during bottlenecks or peak loads.”

In addition to the partnership in the daily business of NC programming, LMT and ScaleNC have also agreed on joint workshops for the next few months, in which both sides would like to work together to develop efficient solutions for complex NC programming tasks.

Contact

LMT Leuchten + Metall Technik GmbH

Dieselstraße 5

D-91161 Hilpoltstein

Germany

https://lmtgmbh.de/

Photo credits: LMT